General information on final drives

Due to the different types and designs, the following content refers to typical final drives used in chain-driven construction machinery.

These usually consist of a hydraulic motor and a flange-mounted planetary gear.

The basic principle can be described as follows:

The final drive is integrated into the existing hydraulic circuit and supplied with hydraulic oil. The system pressure present in the circuit, which varies depending on the machine, moves in a range from approx. 180 to approx. 350 bar.

The hydraulic oil is usually transported in the hydraulic circuit by means of a hydraulic pump (frequently used: gear pump). The direction of flow of the hydraulic oil determines the direction in which the output side of the final drive moves. The flow direction of the hydraulic oil determines the direction in which the output side of the final drive moves.

(Note: the output side is the side on which the planetary gear is located and at the same time, the sprocket is mounted)

The sprocket sets the chains of the machine in motion depending on the flow direction of the hydraulic oil whether forwards or backwards.

If we look at the hydraulic motor of the final drive, its main task is to convert hydraulic energy into mechanical work and ultimately into a rotary motion.

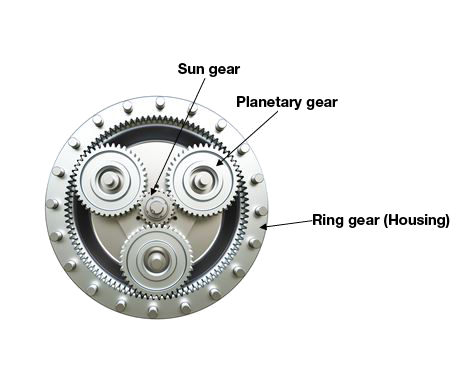

The planetary gearbox takes on the task of converting torques and speeds and adjusting mass inertias. The core of this is the gearing. So-called planetary gears move around a sun gear that is driven. The planetary gears are used for power transmission. The ring gear (housing), on which the sprocket is mounted, usually has an internal toothing into which the planetary gears engage.

The transmission ratio is the ratio of the speed at the input to the speed at the output and is determined by the size of the sun gear to the size of the ring gear (housing).

Essentially, it can be assumed that the higher the torque at the ring gear (housing), the lower its rotational speed. In this context, the efficiency of the planetary gear should be mentioned.

Principle design – Planetary gear unit

Furthermore, there are multi-stage planetary gears. These gears are often designed in a way that several sun gears with different pitch diameters (number of teeth) are available while the internal toothing of the ring gear remains the same. Depending on the desired speed or torque at the ring gear (housing), the respective sun gear is engaged.

In this context, assuming a constant internal toothing or constant size of the ring gear – the larger the respective sun gear is, the smaller are its rotating planetary gears and the smaller is the factor of the transmission ratio.